In the following, we will identify the artificial stone nano cement plast production line:

What is artificial stone nano cement plast?

Are the raw materials required for artificial stone cement plast available?

Definition of artificial stone cement plast resin?

What is resin? is resin used in cement plast technology?

Are concrete machines (mixers and vibrating tables) is it usable in this technology for the production of artificial stone? The difference between the concrete vibration table and the artificial stone cement plast vibration table

The difference between the concrete vibration table and the artificial stone cement plast vibration table

The difference between centrifuges mixer to produce artificial stone cement plast and concrete mixer

Why is the cost of production (cost of goods) in the artificial stone cement plast is low!?

What are the reasons for the low cost of artificial stone cement plast compared to other technologies?

What is the quality of artificial stone cement plast?

How much space is needed to launch any artificial stone cement plast production line? What is artificial stone nano cement plast?

What is artificial stone nano cement plast?

Artificial stone nano cement plast technology with using a variety of special polymer materials and nano compounds, the molecular bonding of minerals is deformed by polymerization reactions and the physical resistance is 2 to 3 times more than the concrete and natural stone used in the market.

Are the raw materials needed for artificial stone cement plast available?

Are the raw materials needed for artificial stone cement plast available?

All minerals used in artificial stone cement plast technology in mines of Iran are available at very reasonable prices and their supply is done in accordance with the required standards easily. Also, all relevant additives (polymeric and nano materials, as well as chemicals) are introduced internally by the relevant links to the technology applicant. and applicant for cement plast technology, according to the standards additives, are buys. however, if a technology applicant fails to provide a particular material for any reason, HUNAM company will be required to provide that particular material to the applicant for the artificial stone production line.

What is resin? is resin used in cement plast technology?

Definition of Resin: In any technology associated with polymer or chemical materials, one of the main materials is called resin. any material made up of a combination of several polymeric materials - nano or chemical, resin is called.

There is also resin in artificial stone cement plast technology (But not the resins in the other industries). but this substance is not 100% ready, not available, because this material will not be 100% not ready for portability (Due to the turbulence of road will be two phases and its properties will be lost) this material will be 80% ready to be portable. on the other hand, this material should be made to produce based on the weather conditions, the results of the minerals test, based on the final product (type of product), ambient temperature, and materials.

artificial stone cement plast resin by generating negative ions (negative electrical charge) in cement molecules and the use of molecular repulsion property, takes the tendency to absorb water from cement and it reduces the amount of water consumed. by reducing the amount of water used in the cement plast mix, we achieve resistance and other special features. Are concrete machines (mixers and vibration tables) usable in this technology for the production of artificial stone?

Are concrete machines (mixers and vibration tables) usable in this technology for the production of artificial stone?

No, concrete machines can't be used to produce artificial stone cement plast in any way. below we examine some of these cases:

Non-Standard Vibrating Table - Non-Standard Mixer: Vibration table has been defeated due to inadequate material and material size. how long will you waste costs?

Vibrating Table: View the specifications of the vibration tables on the site and the price files. Purchase from any company, please purchase the same specifications as listed in our list, which don't have too much damage. when buying, be sure to get technical specifications from the manufacturer or seller and according to that specification, take delivery

Vibrating Table: View the specifications of the vibration tables on the site and the price files. Purchase from any company, please purchase the same specifications as listed in our list, which don't have too much damage. when buying, be sure to get technical specifications from the manufacturer or seller and according to that specification, take delivery

Difference between vertical vibration machine (Vibrating table with vertical blows) and concrete vibrating table (Vibrating table with horizontal blows):

Difference between vertical vibration machine (Vibrating table with vertical blows) and concrete vibrating table (Vibrating table with horizontal blows):

due to the time limit in the technology of artificial stone nano cement plast, to create a series of physical and appearance features in products, it is necessary to use special vibration tables, which in a short time, can create the required specifications for this technology.

This is important: the mold genus defines the type of vibration required in the production of the product: if the mold is dry, like ABS and HP molds, fiberglass molds and... need to create vertical blows on the vibration table, and if the molds are soft, like silicone molds, rubber molds, polyurethane molds or soft PVC molds, vibrating table with horizontal blows are needed. also the type of molds in the production of artificial stone, is selected depending on the type of product and side features such as glossiness. most of the molds of this technology are ABS and HP.

There is no time limit on vibration mosaics (concrete mosaics) and that is why the vibration tables are made in a low width and long length. the duration of the vibration in concrete is unlimited (Only for homogeneous concrete mortar), for this reason, these vibration tables have horizontal blows and rubber molds (in concrete mosaics) along with mix (concrete) are transferred to the end of the vibrating table within 3-5 minutes and then collected.

In the technology of artificial stone cement plast (HUNAM Company), requires blow wavelength, appropriate angle of the vibration blows | vibration table, frequency, impact power, vibration range and... which vibrating machines in the market can't create these vibrations. example for one of these features: the angle of blows on vertical vibrating machines, is special for artificial stone cement plast technology is vertically. and for this reason, need for a manpower, to move the molds at the vertical vibration machines level.

The required amount of vibrations in cement plast products is limited. the maximum time is 45 seconds and in different designs (depending on the shape and dimensions, etc.) this time is different. over limit, cause decrease in quality, and increasing the vibration time in nano cement plast technology also results in poor quality in the final product.

The springs included in these vibration table machines (Vertical vibration) are manually, with the proper alloy formulation, to create the vibrations required in the product, are made. there are also no vibrations in the bases, and the sound of the vibrating table has been minimized.

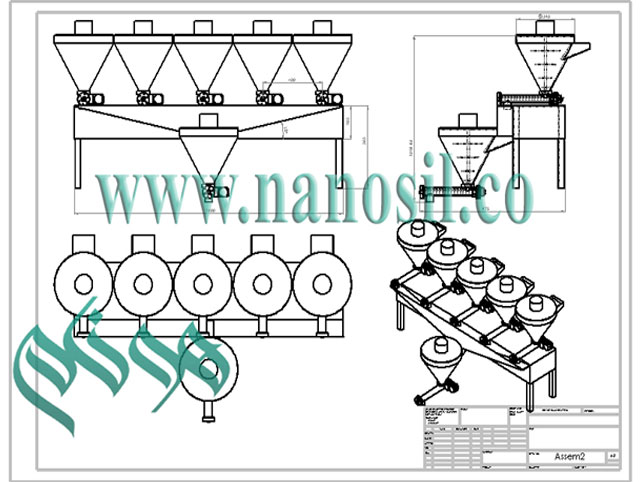

Because of the use of two vibrating electric motors in standard tables, as well as optimal dimensions, each time the shape of the molds is changed, it is easy to create vertical blows or horizontal blows by changing the rotational speed of the vibrating motors. in vibration tables, with a vibrator electromotor, or vibration tables with a low width and long length (even with two electric motors), You can't create both vertical blows and horizontal blows. The difference between a centrifuge mixer for the production of artificial stone nano cement plast and concrete mixers(The picture above shows the concrete mixer):

The difference between a centrifuge mixer for the production of artificial stone nano cement plast and concrete mixers(The picture above shows the concrete mixer):

Concrete mixers do not have the power to blend the sticky materials with the erosion of Plast Cement technology. concrete mixers, at the time of making the mixture of cement plast (due to lack of desired properties), finally, it carries a mixture (material) of artificial stone nano cement plast and rotates it (inside the mixer). in this case, without proper mixing, the chemical-polymeric reactions in the material are not completely performed and the production of the product (artificial stone cement plast) becomes impossible. some of the compounds (raw materials used) in synthetic stone cement plast are non-solvent. as a result, whit using the properties of centrifuge mixer and nano materials, their molecular tissue breaks down and become solvent (break of insoluble matter in polymeric solvents).

Why is the cost of production (cost of goods) in the artificial stone cement plast is low!? (why cement plast prices are lower than other technologies)?!

side costs and the production in artificial stone products is low, for the following reasons:

In artificial stone nano cement plast technology, these products (artificial stones) require a specific temperature to process, which controls the temperature of the material, with using nano and polymer compounds.

In the production of artificial stone cement plast products, due to the use of certain polymeric and nano compounds, it is not necessary to do the curing (steam bath) or irrigation of the product.

In the production of artificial stone cement plast products, there is no need for operations such as sub (polishing), polishing, priming, and a specific device for post-production operations. for shiny products, special operations have been carried out during combinations of materials, and they are opaque or glossy after production, it is clear

Color combinations or special veins (Simulation of natural stones (marble and granite) all were in time of production and when mixing materials, it is created. after preparing the material, molding is run and mixed maintenance with mold is done. after treating, the product opens from the molds, packed, and ready for use.

In the production of artificial stone nano cement plast products, to increase the resistance of this product, there is no need to depot the product What is the amount of artificial stone cement plast profits?

What is the amount of artificial stone cement plast profits?

It has been observed that some artificial stone providers point to their advertising: invest $ 15,000 and earn $ 5,000 a month.

It should be noted that in some months, this amount of profit may be insignificant in the manual production line. but to many of the policies, the way of selling, who and with what terms, the product is sold, sales flooring or facade... the profit level is dependent. there may be a 1000 dollars a month or 3000 dollars a month, all this will depend on the investor himself and the sales policies as well as sales area,

So, the profitability of the cement plast production line will be very high, provided that, good sales and marketing policies are taken and also, the product should be of high quality and high beauty. but if you buy a non-standard production line, you will not get a high-quality product at all, and you will not get high profits.

How much space is required to launch any artificial stone cement plast production line?

How much space is required to launch any artificial stone cement plast production line?

To set up a manual production line (non-expandable), about 100 square meters of space and 100 square meters of storage space are required.

In order to set up a manual artificial stone cement plast production line (with the ability to upgrade to higher sets), about 150 square meters of production space and 150 square meters of storage space are needed.

In these sections, there is no need for high altitude lounge ceiling

To launch a semi-automatic production line of artificial stone nano cement plast, it requires about 300 square meters of space and 150 square meters of storage space.

To launch the automatic production line of artificial stone cement plast, the first type, requires 400 square meters of production space and 200 square meters of warehouse space.

In production lines of more capacity, to the amount of production space and warehouse will be added, the amount of space above is to produce a work shift, and as the work shift increases, more space and more storage are needed. in the automatic and semi-automatic production lines, it is required that the height from the floor to the ceiling of the hall is 6 meters in the installation of machinery. the remaining space of production and warehouse is 4 meters or less.

How long are the useful life of artificial stone cement plast production line machines, mixers and vibration tables in the manual production line and automation equipment in the automatic production line?

How long are the useful life of artificial stone cement plast production line machines, mixers and vibration tables in the manual production line and automation equipment in the automatic production line?

If the buyers of the production line, either manual or automatic, according to the repair and maintenance offered in the training courses, the useful life of the machine is 15-18 years. for example, in the manual production line, timely replacement of gear oil, engine wrenching, phase control, not mixing to much of excessive material that is mentioned, and... prolonging the life of the machine. another example: in the case of a mixer, every 18 months, mixer blades need to be replaced and every 36 months it is necessary to replace the arms.

But if the production line is non-standard, it will have high maintenance costs. due to the technical specifications of the artificial stone cement plast production lines (made by BAGHERI Machine Manufacturing Co.), the cost of repair and maintenance of the machine is very lower.

What is the quality of artificial stone nano cement plast?

What is the quality of artificial stone nano cement plast?

The quality of artificial stone is not summarized only in a special mineral and or a machine or polymer and nano compounds. but in product quality, all production factors will play a role, these factors include:

type of soil or minerشl material, the result of the tests and standards required in this regard, the type and amount of vibration of vertical vibration | vibrating table with vertical blows in dry molds, the property of the centrifugal mixer and the strength of the mixing cement plast material, polymer and nano compounds, molds for production of cement plast and...

Due to a chain of effective factors in the quality of nano cement plast products, if any of the factors in this chain are not met (Raw materials, machinery, polymer materials, nano resin, molds, etc.), the quality of the final product (Artificial stone cement plast) will not be desirable.

For example:

HUNAM's molds manufacturing are manufactured with using polymer-quality materials. if the recycled materials are used in molds or the manufacturing system is injectable, the quality of the product in question will be varied in terms of product shine and opaqueness (50% related to the mold ).

Do non-expert individuals with a non-standard artificial stone production line make it difficult for producers who manufacture the standard product line?

Do non-expert individuals with a non-standard artificial stone production line make it difficult for producers who manufacture the standard product line?

Some investors, for whatever reason, are buying non-specialized and non-standard machines, after purchasing and commissioning, these companies realizes that they are non-standard equipment, and training course was non-specialized. which there are several solutions: unit shutdown, abandoning equipment and machinery and purchasing standard equipment and passing training of produce in the form of specialty, or produce poor quality products and stay in the market at low prices

Many people who buy non-standard production line, after setting up and find out the very low quality of products, due to the lack of science of artificial stone production and unrelated machinery, the unit closes after launch. these people grow like mushrooms and will be removed from the market in the short term.

Because they have to pay at first, and all or most of their past costs have been lost. Ten percent of people use this stage (replacing machines and making high quality products), and 90% of people enter the third stage. The third way, staying on the market by producing a poor quality product and at a lower price: this way, paddle in the swamp is, because of the lack of science in the production of stone stairs and facades (Machines do not have the power to build these products, and the product is damaged, they can't take risks in the case of facades, and provide a poor quality product.) which is the main benefit of this work. therefore, they are producing non-quality flooring, with this mindset, which Ultimately, the product will loose. these companies that use the non-standard production line can't even produce high quality mosaics, all products, even in a manufactured mixer, differ in their colors (especially in sensitive colors), adhesion strength to the surface has low, they don't have glossiness, the compressive and flexural strength of the product is low. for this reason, these people are shutting down a manufacturing workshop after six to one years after production.

The third way, staying on the market by producing a poor quality product and at a lower price: this way, paddle in the swamp is, because of the lack of science in the production of stone stairs and facades (Machines do not have the power to build these products, and the product is damaged, they can't take risks in the case of facades, and provide a poor quality product.) which is the main benefit of this work. therefore, they are producing non-quality flooring, with this mindset, which Ultimately, the product will loose. these companies that use the non-standard production line can't even produce high quality mosaics, all products, even in a manufactured mixer, differ in their colors (especially in sensitive colors), adhesion strength to the surface has low, they don't have glossiness, the compressive and flexural strength of the product is low. for this reason, these people are shutting down a manufacturing workshop after six to one years after production.

So non-expert individuals can, in the short term, cause problems for standard manufacturers, they can repel these problems by adopting a policy of producing high-profile products and focusing less on the production of flooring, and lack of effort in competing in the flooring. so in the short term, these non-expert companies are causing a problem, but in the long run, it is in the interest of the standard manufacturer.

So, the action of non-expert companies in the projects it is in the interest of standard manufacturers. always remember, low prices, due to low quality products in the short term is.