production automation lines for antique stones And flooring to produce a variety of products, Designed For those who want a low cost Semi-automatic production lines with acceptable capacity.

It should be noted that these production lines Are standard And the ability to produce various antique stone products,Artificial stone Facade Guillotine, Flooring, mosaics, Stairs stone and Artificial under the stairs, Polymer curb and ... as standard

Production automation lines-Semi-automatic stone and antique artificial flooring, There are three different types that are referred to below

Production automation lines-Semi-automatic stone and antique artificial flooring, There are three different types that are referred to below

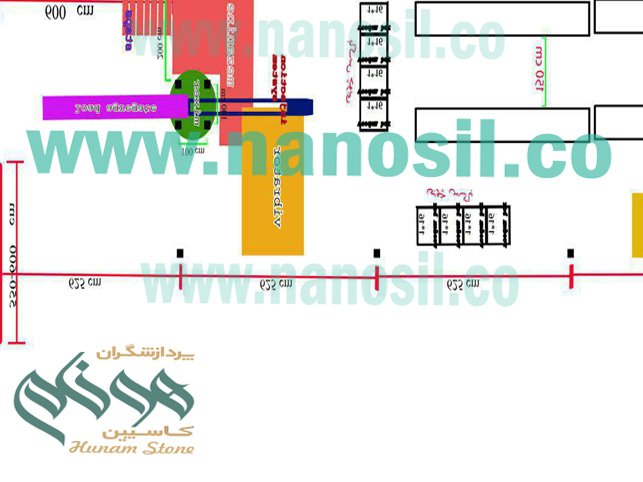

Automation Production Line - Semi-automatic Standard Artificial Stone Nano Cement Plast Type One With a capacity of 200 to 250 square meters

Automation Production Line - Semi-automatic Standard Artificial Stone Nano Cement Plast Type One With a capacity of 200 to 250 square meters

Loaded aggregate and adhesive material system: With custom envelopes with 4 mm reinforced sheet with automatic opening valve With a width of 60 cm and a length of 6 meter At an angle of 45 ° to 60 ° and 1 meter Trail With iron size 10, With wire tow 10 with 12 meters long, With two pieces of cast iron reel with 206 ball bearings, Capacity 400 kg With four-horse three-phase transmission engine and the halo shaft gearbox 110

*Note: Some companies have attempted to Provide rail loading system With a lot of length And a huge slope, also with relevant hopper profile With low volume To reduce the amount of sheet used, Rail system production With a very poor chassis profile And low length without preservatives, not using the motor & gearbox on top of the machine And the cost is done For the horizontal space of the upper part And installing the engine in the bottom, the mineral loading system and…

Then some minerals When pouring in the mixer, Didn't go into the mixer And loading would not be complete, also because of the weak profile at rails section Causing bending, the loaded Angle should be between 45 and 55 degrees on rail system. For example, for loading at a height of 3 meters The inlet of the mixer should be placed in the direction of the angle of the lifter And use heavy iron number 10.

Artificial Stone Cement Plast Mixer : 10 hp TURKISH YILMAZ motor And gearbox 150 Custom, And special 33 mm centrifugal arms with Arm Adjustable, with anti-friction blades Floor sheet thickness is 15 mm and Mixers wall thickness is 8 mm, with 15 Mm mixer diameter And body height 55 Cm Has a material exit part to form of Manual gearbox, Lower gearbox, The size of the machine with a nominal capacity of 400 kg of artificial stone material, Capacity of making 500 kg of pasty glue And 600 kg powdered glue with easy valve opening equipped Manual gearbox.

Vertical Vibration System In dimensions 1 × 2 m (Artificial stone vibration table), With two 500 kg Chinese High quality vibrating motors, with a plate surface of aerodynamics vibration table And chassis 16, Special metallurgical springs.

Artificial stone molding machine: Mold injection system with 400 kg hopper capacity And a valve with a pneumatic jack Equipped with electrical valve and wind protector control And a screw carrying material of 2.5 meters in length, With 5.5 horsepower three-phase engine And the Halo Shaft gearbox 110 And weighing system With digital display and pneumatic pedal, with rinse valve and evacuation gate rinse With a 2.5- manisman tube With support holders.

Artificial stone molding machine: Mold injection system with 400 kg hopper capacity And a valve with a pneumatic jack Equipped with electrical valve and wind protector control And a screw carrying material of 2.5 meters in length, With 5.5 horsepower three-phase engine And the Halo Shaft gearbox 110 And weighing system With digital display and pneumatic pedal, with rinse valve and evacuation gate rinse With a 2.5- manisman tube With support holders.

*Attention : Observed in many cases, Some sellers and machinery dealers Introducing uncontrolled molding system With inverter Or without pneumatic gates And its controllers Using a screw system Instead of Screw U system and… Respected buyers should be notified,that these systems because of non-control of the amount of material entering inside molds or delay of system Due to reduced engine speed and gearbox, Or because of high speed because of constant rotation of the system and ... Absolutely non-normative And in the not too distant future If you buy this non-standard equipment They will have to change them.

Central control panel machines: With dimensions of 80 * 60 * 20 cm,Equipped with 12/25/18 amp contactors , with phase control, And miniature fuses for the respective machines And Accessories, With thermal sensor And cooling fan With the Start Stop keys for Main devices, Along with the inverter For control of the 5,5 horsepower screw molding and ...

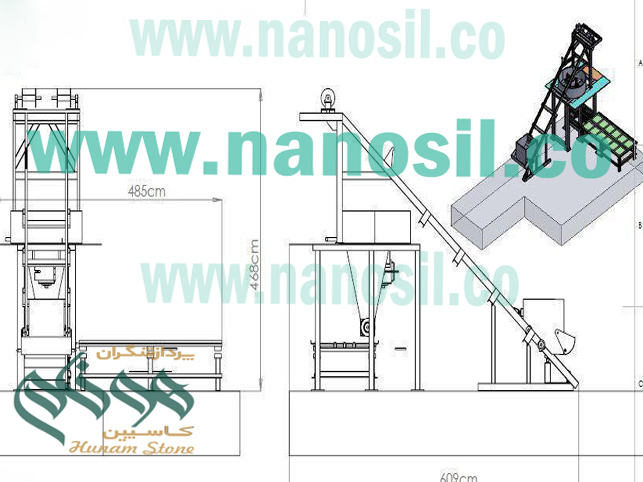

The standard production line of Artificial Automation - semi-automatic Type II, With a capacity of 300 square meters with the following specifications:

The standard production line of Artificial Automation - semi-automatic Type II, With a capacity of 300 square meters with the following specifications:

Artificial stone aggregate loaded system And solids for produce tile glue: With custom envelope with a sheet of 6 mm rein forced With automatic pop-up valve With a width of 80 cm and a length of 8 meters At the 60th angle with towline 12 and 16 meters long,With two special cast iron pulley, With a capacity of 600 kg With 5/5 horsepower three-phase motor and hollow shaft 130 gearbox

Artificial Stone Artificial Mixer: 15 HP Three-phase motor, Floor plate thickness 15 mm and Wall thickness 8 mm, with adjustable arm size 35 designed by pan, With a manual gearbox exits, With a diameter of 140 cm And body height 55 cm And the volume is 900 liters, With a capacity of 500 kg normal density As standard, And equivalent to 750 kg of normal density of ultra-light materials, pasty glue With a capacity of 850 kg And powdered adhesive with a capacity of 1000 kg

Central Control panel of the machine: For a 300 meter semi-automatic line second type, To control and command all machines, Equipped with 25/32/18 amp contactors, With phase control , And miniature fuses for the respective machines And Accessories, With thermal sensor of machines and thermal sensor of panel temperature And cooling fan, With the Start Stop Keys of machines, In addition to the inverter to control the 5,5 horsepower screw molding, along with PLC for semi-automatic production, Automatic loading of main add-ons And control the relevant pumps and ...

Vibrating Table Machine:The vibrating table in size 3 × 2 meters and 8 mm surface sheet, With two 1300 kg three-phase vibration motors, With 16 chassis and central wide chassis, Special metallurgical springs And the aerodynamic surface and weight system table.

Molding machine of adhesive and stone: U material transfer screw With 2 Butterfly Valves Equipped with a pneumatic jack-Two sets of electrical Valve and one water trap & pressure control Length of 3.5 meters With a 5/5-horsepower electro motor And the hollow shaft Reduction, Comes with a hopper with a thickness of 3 mm With a volume of 600 kg, With a 2.5 inch MANNESMANN tube shaft, Two scales for loading the mold With dimensions 50*50 cm with the touch screen,

Molding machine of adhesive and stone: U material transfer screw With 2 Butterfly Valves Equipped with a pneumatic jack-Two sets of electrical Valve and one water trap & pressure control Length of 3.5 meters With a 5/5-horsepower electro motor And the hollow shaft Reduction, Comes with a hopper with a thickness of 3 mm With a volume of 600 kg, With a 2.5 inch MANNESMANN tube shaft, Two scales for loading the mold With dimensions 50*50 cm with the touch screen,

Closed-circuit pump system 3 hp of Polymer materials, With hopper and Tensile polymer load cell, Sensors and valves And fluid loading system,…

Attention: The above product line if needed According to specifications Ability to upgrade to sections With our implementation is less costly, But if you upgrade to automatic sections, Loaded elevator section The aggregate is removed and Hopper & elevator are added to the section. And the remaining parts are usable and exploitable. Automatic - semi-automatic Artificial Stone Production Line façade stone and mosaic polymer, Third type | With conveyor belt | With a capacity of 250 to 300 SQM along with the following specifications

Automatic - semi-automatic Artificial Stone Production Line façade stone and mosaic polymer, Third type | With conveyor belt | With a capacity of 250 to 300 SQM along with the following specifications

Vibrating table With 300 kg vibration motor, Stationary with a capacity of 2.5 to 3 tons - It has a vibrator engine To save aggregate And alternative materials.

Vibrating table With 300 kg vibration motor, Stationary with a capacity of 2.5 to 3 tons - It has a vibrator engine To save aggregate And alternative materials.

Mixer machine with 3 phases motor 15 hp, And gearbox 185, Anti-friction blades, The thickness of the sheet is 15 mm and Wall thickness 8 mm With a diameter of 140 cm And body height 55 centimeters With a volume of 900 liters, with adjustable arms size 33 m centrifuge designed by pan, It has an automatic material withdrawal section as Engine and Cube gearbox–with automatic pause sensor-With emergency valve control, With a capacity of 400 kg of normal density, And equivalent to 750 kg of normal density of super lightweight materials, pasty glue With a capacity of 850 kg And powdered adhesive with a capacity of 1000 kg.

-central control panel, For the automation line Direction control and command all machines With a 7-inch touchscreen, Artificial Stone Vibrating Table Machine With vertical blows | Vertical Vibration table In dimensions of 3 × 2 meters And the plate surface of the table is 8 mm, With two 1300 kg three-phase engines, With chassis 16 And the central chassis of a heavy wide wing, Special metallurgical springs, and Aerodynamics surface – along whit weight system table –turn off turn off

-central control panel, For the automation line Direction control and command all machines With a 7-inch touchscreen, Artificial Stone Vibrating Table Machine With vertical blows | Vertical Vibration table In dimensions of 3 × 2 meters And the plate surface of the table is 8 mm, With two 1300 kg three-phase engines, With chassis 16 And the central chassis of a heavy wide wing, Special metallurgical springs, and Aerodynamics surface – along whit weight system table –turn off turn off

Façade Stone molding system And mosaic with screw transfer material With 2 valves as pneumatic - electric valve Accessories And the related Protective control, Length of 3.5 meters With a 5/5-horsepower YILMAZ motor and hollow shaft gearbox with speed control and inverter

With 4 special loud-cells of mixer artificial stone for weigh in of row materials

Below are some of the pictures of the semi-automatic production line of artificial stone with a capacity of 300 square meters

Below are some of the pictures of the semi-automatic production line of artificial stone with a capacity of 300 square meters