Quartz engineering stone products due to the type of materials and their production method, the need for machines will be complex and costly. also, due to the high cost of these products, the ability to compete with these products in the case of the use of a facade of the building or interior flooring and the like, is very low. therefore, it is possible to change the production process of quartz stone and marble products that are based on polymer.

One of the advantages of this work (the replacement of engineered artificial stone quartz base from a polymeric base to a cement base) can be pointed out as follows:

The cost of setting up a similar production line of Quartz stone (artificial stone quartz cement base) compared to the quartz stone production line (polymer base), it is much less, also, the need for very complex machines is eliminated. The cost of artificial stone quartz and granite and marble will be much less than the cement base slabs of the quartz stone and the slabs of the polymer base, therefore, it will enjoy competitive power over other products. it can also be used for more general use.

The cost of artificial stone quartz and granite and marble will be much less than the cement base slabs of the quartz stone and the slabs of the polymer base, therefore, it will enjoy competitive power over other products. it can also be used for more general use.

Strength of products of artificial stones similar to Quartz Cement base slabs will be better than the polymer based slabs against sunlight and atmospheric agents.

If the company is a manufacturer of artificial stone facade & mosaic polymer products,materials for the production of floor slabs stone and façade of cement base quartz stone, can be made with the desired equipment. therefore, in order to complete the production process, it is necessary to add the accessories to the production line.

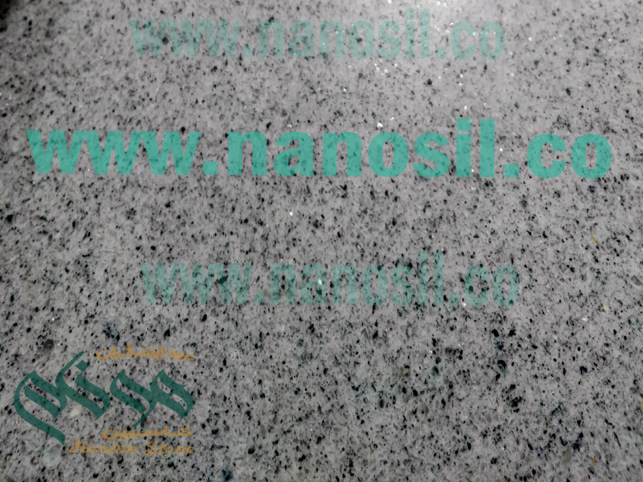

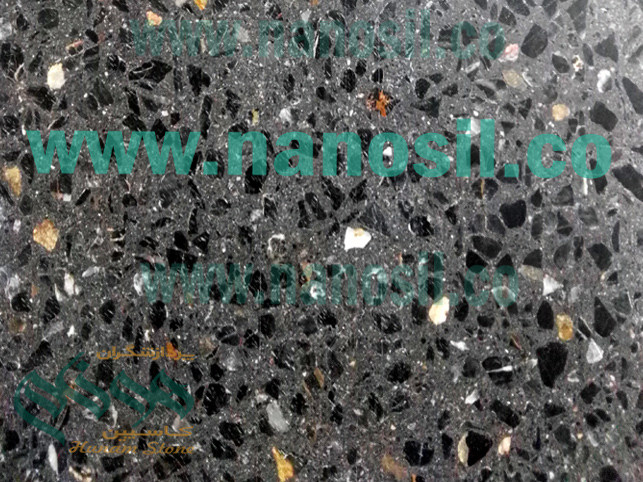

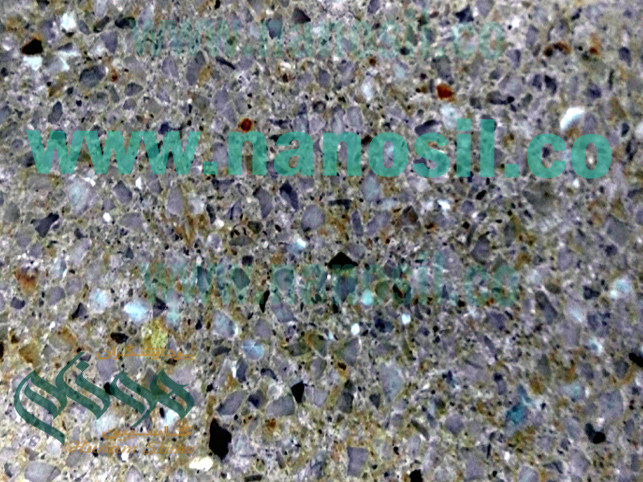

Artificial stone quartz cement based products can be produced with a thickness of 12 mm and above. Below we will examine some cases:

Below we will examine some cases:

The main equipment and machinery in this product (similar to the stone facade of the quartz and marble of the cement base) are the same equipment of the production line of NANO facade stone & mosaic polymer. Raw materials and formulations of production are different, after fabricating the material into an artificial stone facade & mosaic polymer mixer, the mixture is prepared in a vacuum press vibrating system.The dimensions of the vacuum press machine are in accordance with the size of the final product.A vibrating press system with a capacity of 80 to 100 tons and a water vapor must be provided.

In order to set up the production line of quartz flooring facade with vacuum vibrating press system should be designed according to the budget of machinery. after hardening of the product, from 24 to 48 hours after production, the product will be in sub and polishing machines, the higher the number of heads (Sub-head), the output will be better, and the transparency and polished product will be achieved. Generally, the sub machine (head), 14 heads to up for this work along with the sub-calibrated, 3 head is required

Generally, the sub machine (head), 14 heads to up for this work along with the sub-calibrated, 3 head is required

Fortunately, our country is rich in minerals, and polymer materials, and about one and a half percent of the total demand for imports in this technology is required.

from the cement based quartz stone, can be used for interior and exterior facades, interior flooring, parking and sidewalk floors, stone steps, floor elevators and more.

Stay in touch with us for technical advice