Cultured Marble & Granite Artificial Stone Production Line Manual System, Solid surface Artificial Stone Manually Equipment

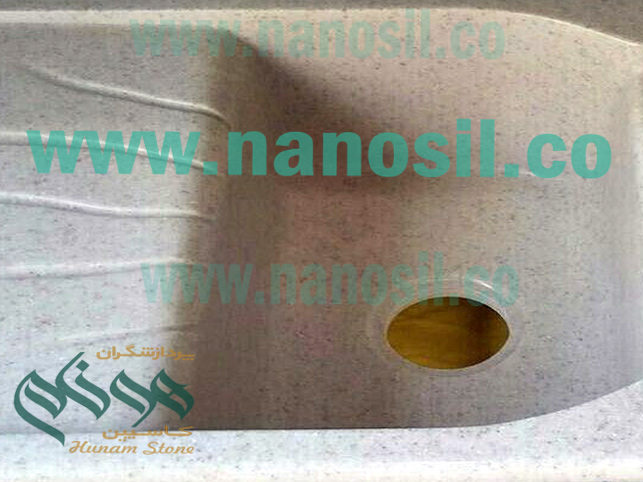

One of the most used and most suitable products for decoration inside the building and toilets, kitchens-stores and offices and ... use of cultured marble-granite & solid surface(Also known as CORINNE in the Iranian market)

To produce these products, you can use a variety of automation techniques, manual and traditional, as well as fully automatic.(a joint production line with artificial quartz rocks or specifically artificial marble) here is an explanation of some of the required accessories for manual production lines and with the minimum capital of artificial marble. (cultured marble artificial stone manual equipment production line)

To produce these products, you can use a variety of automation techniques, manual and traditional, as well as fully automatic.(a joint production line with artificial quartz rocks or specifically artificial marble) here is an explanation of some of the required accessories for manual production lines and with the minimum capital of artificial marble. (cultured marble artificial stone manual equipment production line)

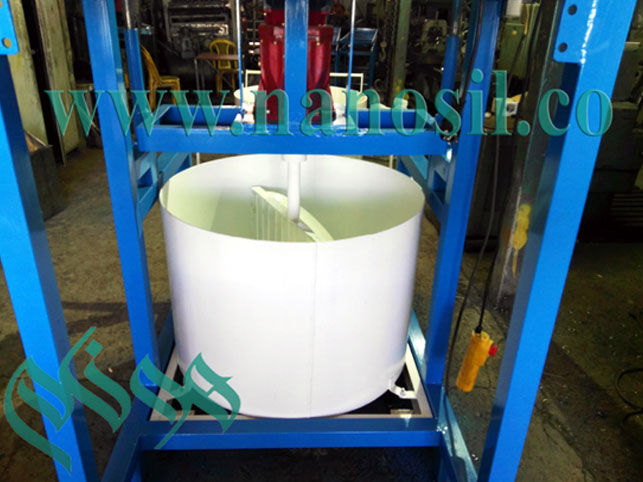

The first machine to produce marble and granite products, or similar to CORINNE, is a special mixer for this work. HUNAM Machine Manufacturing, these mixers are presented to applicants with different capacities and specifications, which are referred to in part.

The first machine to produce marble and granite products, or similar to CORINNE, is a special mixer for this work. HUNAM Machine Manufacturing, these mixers are presented to applicants with different capacities and specifications, which are referred to in part.

manual mixer for artificial stone cultured marble-granite & solid surface with capacity 200-300-400-500 KG with top-down injection method

For the production of marble and granite materials with a capacity of 200 kg, the need for a minimum of 3 HP three-phase electrical motor, with vertical gearbox, the direction of rotation of the mixer blades of the artificial stone marble & granite,special blade with erosion resistant sheet with a winch motor to move the blade and the main engine up and down to exit the material furnace with the corresponding buttons, wheeled furnace with a capacity of 250 KG with the

thickness floor of the sheet is 6 mm and body thickness 4 mm, exit material manually and from the top of the furnace, ability of making between 100 and 250 kg according to consumables and formulations.

For the production of marble and granite materials with a capacity of 300 kg the need for an motor 5.5 horsepower three-phase, the gearbox is for rotation of the artificial stone mixer blades, special blade with elastic resistant sheet with a winch motor to move the blade and the main engine up and down for exit the furnace material with the corresponding buttons, wheeled furnace with capacity 350 KG with the thickness floor of the sheet is 6 mm and body thickness 4 mm, exit material manually and from the top of the furnace, ability of making between 200 and 350 kg according to consumables and formulations.

For the production of marble and granite materials with a capacity of 300 kg the need for an motor 5.5 horsepower three-phase, the gearbox is for rotation of the artificial stone mixer blades, special blade with elastic resistant sheet with a winch motor to move the blade and the main engine up and down for exit the furnace material with the corresponding buttons, wheeled furnace with capacity 350 KG with the thickness floor of the sheet is 6 mm and body thickness 4 mm, exit material manually and from the top of the furnace, ability of making between 200 and 350 kg according to consumables and formulations.

For the production of marble and granite materials with a capacity of 400 kg, the need for a 10 HP three-phase electrical motor, with vertical gearbox, the direction of rotation of the mixer blades of the artificial stone marble & granite,special blade with erosion resistant sheet with a winch electro-motor to move the blade and the main engine up and down to exit the material furnace with the corresponding buttons, wheeled furnace with a capacity of 400 KG with the thickness floor of the sheet is 8 mm and body thickness 6 mm, exit material manually and from the top of the furnace, ability of making between 350 and 400 kg according to consumables and formulations.

For the production of marble and granite materials with a capacity of 400 kg, the need for a 10 HP three-phase electrical motor, with vertical gearbox, the direction of rotation of the mixer blades of the artificial stone marble & granite,special blade with erosion resistant sheet with a winch electro-motor to move the blade and the main engine up and down to exit the material furnace with the corresponding buttons, wheeled furnace with a capacity of 400 KG with the thickness floor of the sheet is 8 mm and body thickness 6 mm, exit material manually and from the top of the furnace, ability of making between 350 and 400 kg according to consumables and formulations.

For the production of marble and granite materials with a capacity of 500 KG the need for an motor 15 horsepower three-phase, the gearbox is for rotation of the artificial stone mixer blades, special blade with elastic resistant sheet with a winch motor to move the blade and the main engine up and down for exit the furnace material with the corresponding buttons, wheeled furnace with capacity 600 KG with the thickness floor of the sheet is 8 mm and body thickness 6 mm, exit material manually and from the top of the furnace, ability of making between 450 and 600 kg according to consumables and formulations.

For the production of marble and granite materials with a capacity of 500 KG the need for an motor 15 horsepower three-phase, the gearbox is for rotation of the artificial stone mixer blades, special blade with elastic resistant sheet with a winch motor to move the blade and the main engine up and down for exit the furnace material with the corresponding buttons, wheeled furnace with capacity 600 KG with the thickness floor of the sheet is 8 mm and body thickness 6 mm, exit material manually and from the top of the furnace, ability of making between 450 and 600 kg according to consumables and formulations. The second main machine needed to produce marble and artificial granite, the vibration table has a width of 60 cm and a length of 400 cm. this vibration table has an adjustable vibrating motor and with weighs and hits 300 KG. this is a vibrations table, special for longitudinal stones.

The second main machine needed to produce marble and artificial granite, the vibration table has a width of 60 cm and a length of 400 cm. this vibration table has an adjustable vibrating motor and with weighs and hits 300 KG. this is a vibrations table, special for longitudinal stones. Except for the above, raw material, special mold, and shop equipment and accessories are required for production.

Except for the above, raw material, special mold, and shop equipment and accessories are required for production.

If you need to produce a larger product, the same pages of CORINNE or wood veneer stone with a final length of 300 CM, the third main device is the Vibration work table for the production of various types of stones and sinks with specific dimensions.The length of this table is 300 cm and its width is 200 centimeters. with a vibrating motor is 500 kg , adjustable, considered to be.

If you need to produce a larger product, the same pages of CORINNE or wood veneer stone with a final length of 300 CM, the third main device is the Vibration work table for the production of various types of stones and sinks with specific dimensions.The length of this table is 300 cm and its width is 200 centimeters. with a vibrating motor is 500 kg , adjustable, considered to be.