New needs of some buildings and organizations, the speed at which work is performed, Reasonable price, Seamless and integrated flooring and… in some organizations, such as hospitals, integrated flooring in the operating room and other rooms that are seamless and also anti-acid properties,with absorbing zero water, antibacterial, without soil infiltration and darkness in the tissue and ... is very important.

So in order implement flooring with different characteristics, for interior space of the room and the building and for outdoor and outside the building, parking and sidewalks from two different bases, with the implementation method - different making methods, with different formulations and different properties can be used which to each of them and needed required accessories, it is noted:

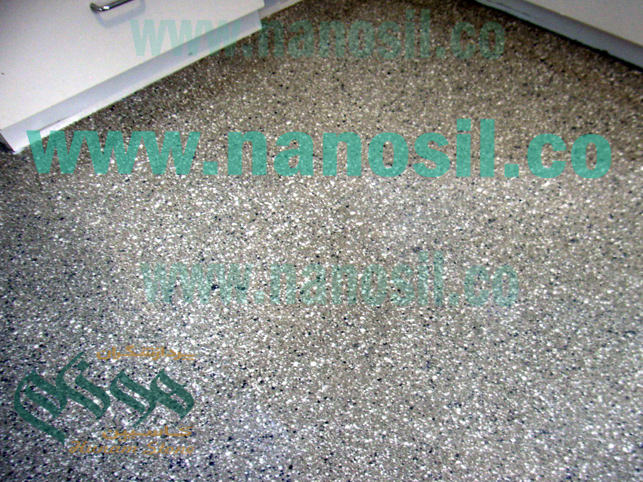

Produce flooring artificial stone cultured marble & granite – solid surface and Quartz seamlessly polymeric base: Polymeric base floorings in monochrome modes, simulation of marble and granite, in very high color variation, with the ability to run in two ways with final coating and without the need for polishing,and without final coating and with sub ability and polishing.

Final-cost of integrated flooring polymer-based compared to integrated flooring cement base has a higher price, therefore, these flooring can be used in the open area and in the parking, but the profit in public places, for buyers will be unless the properties of the integrated flooring polymeric base, such as anti-acidity and..., are to be considered. Advantages of polymeric base flooring, can be mentioned:

Advantages of polymeric base flooring, can be mentioned:

The ability to implement polymeric flooringin the form of monochrome, Multicolor, in the form of marble and granite, in the form of similarities of Granite

Ability to run seamlessly on a large scale

The ability to control the stiffing and drying time of the floor

Absorption property of zero water, as a result, these flooring have anti-acid properties.

Antibacterial properties, because of the lack of microscopic holes and also the absorption of zero water, because of the using vibration system and different meshing when making

Ability to run in low thickness (at least 5 mm) and higher thicknesses

In some special formulation (similar engineering stone as a flooring), ability to lighting in different parts

In the formulation of integrated flooring with ability to polishing, polishing capabilities in the future are also available

Low product erosion also very high adhesion to the working surface

The ability to repair the floor in the event of severe damage and repair of floor plumbing and ...

Thermal tolerance up to 200 ° C

And other item's tip: Polymer base integrated flooring products in terms of formulation Similar to artificial granite marble stones, quartz and solid surface, with different executive practices.

tip: Polymer base integrated flooring products in terms of formulation Similar to artificial granite marble stones, quartz and solid surface, with different executive practices.

So they will be in the category of artificial engineered stones. Also, because the mixer in this type of flooring is the same as the vertical mixer of the sink manufacturing and cabinet stone, and because in the polymer integrated flooring education, these items (sink and cabinet manufacturing) will also be taught, so you can simultaneously produce these products. necessary equipment for the polymer base integrated flooring artificial marble & granite | cultured marble-granite & solid surface | Quartz

necessary equipment for the polymer base integrated flooring artificial marble & granite | cultured marble-granite & solid surface | Quartz

Vertical mixer of artificial engineered stone: the required mixer according to the surface of the coating and the workload is, However, it is recommended to use three-horsepower three-phase perpendicular mixers with a production capacity of between 100 and 250 kg,(According to the formulation and meshing of materials) because of the higher power of the three-phase motor, the three-phase motor is used, for use in the project location and lack of three-phase electricity,can use the inverter (single-phase power transformer to three-phase)

Vibrating plate integrated engineered artificial stone flooring polymer base: to produce sink and stone cabinets and ... the vibrating table is used.but in the production of artificial stone engineering flooring integrated polymer base from the vibrator plate to a size of 50 * 200 centimeters is used with three Vibration motor 100 to 150 kg to compress and balance the materials.

Also, accessories like a 50 kg scale with an error rate of 10 grams and scales from 5 to 20 kg with an error rate of one gram, Industrial agitator drill with double blade and ... are also required equipment.

Also for higher quality, a vacuum system with a capacity of 7 to 8 cubic meters is also needed.

*For more information and advice and answer questions to keep in touch with us.

The advantages of Integrated flooring of artificial stone cement base can be consulted as follows:

Ability to implement integrated cement base flooring in the form of monochrome, marble streaks, in the form of granite, without any restrictions on the color spectrum

The strength of the paints used on the integrated cement base flooring against atmospheric conditions, direct sunlight, acid rain and ... is very high.

Integrated flooring artificial stone cement base,against heat up to 250 ° C indirect heat, in the event of a cold, the temperature will be below zero at 50 degrees centigrade. it also tolerates 400 temperature cycles

The ability to run in the form of seamless in wide level

The ability to control the hardening process and final drying

Water absorption less than 3% with the ability to reduce water absorption by 0.5%

With property of sub & polishing (will not run without sub & polishing) by polishing floor device

Restoration ability and renewed polish in future

Low erosion, without darkness infiltration in tissue of cement base artificial stone integrated

Low cost, high speed

Adhesion to cement surfaces (Ceramic tile and stone surfaces in accordance with the specific conditions of implementation will be sticky) brick surfaces and other surfaces

Bending resistances & compressive resistances, suitable with property of increase the amount of elasticity

Proper resistance against expansion and contraction and non-separation of substructure and ... Integrated cement base artificial stone products, in terms of formulations and mixer machines and in some cases, in the category of artificial stone,Therefore, if necessary, the equipment to be used in the production of some artificial stone products can also be used.

Integrated cement base artificial stone products, in terms of formulations and mixer machines and in some cases, in the category of artificial stone,Therefore, if necessary, the equipment to be used in the production of some artificial stone products can also be used.

Equipment required for the implementation Artificial stone floors cement based integrated:

Mixer: Mixer used in the production of artificial stone flooring seamless cement base, PAN design mixers,but because that is the case should be produced at the place of production, Therefore, the PAN design mixer should be fitted with a 3 horsepower three-phase electro motor (Use of inverter to convert single phase to three-phase power) and gearbox 90 should be used, this special mixer has the capacity to make 200 kg at any time and almost every ten minutes, it can be produced this much that is suitable for producing this product

vibrator page artificial stone flooring cement base like the vibrator page in the integrated artificial stone polymeric base

In this system does not require vacuum machine

Contact us for advice by telephone, or through social networks.