Automatic Artificial Stone Production Line With produce capacity of 900 SQM of building facades, Different façade In dimensions And varied colors And various designs, Flooring types And polymer mosaics, Types of street curbs, Produce of tile adhesives And building adhesives & … 45 to 50 tons Per shift

In designing this production line Certain changes seen Which increases the production capacity. So the difference with artificial stone production line Lack of Material Detection Sensor And related supplies In spite of the presence of a substance detection sensor, With the new programming done Not only shortage is not felt sensors, also Higher quality According to the new programming will provide, Designing this production line Caused That's a new programming for all previous production lines And with a significant cost reduction & we have higher production quality.

Including changes that Increases production capacity in the automatic production line Have been 900 square meters of concrete marble artificial stone The following can be noted

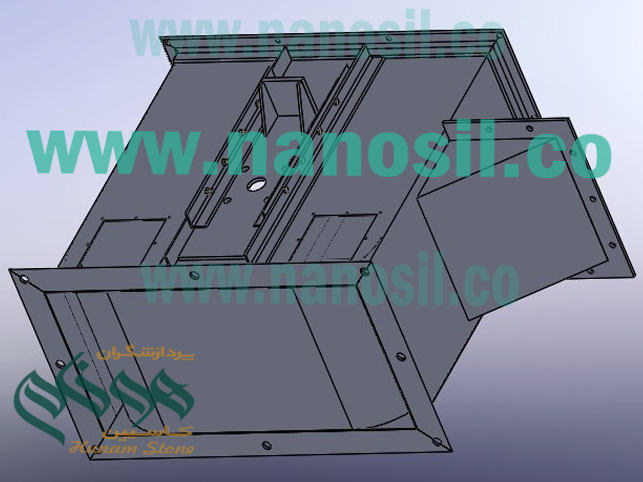

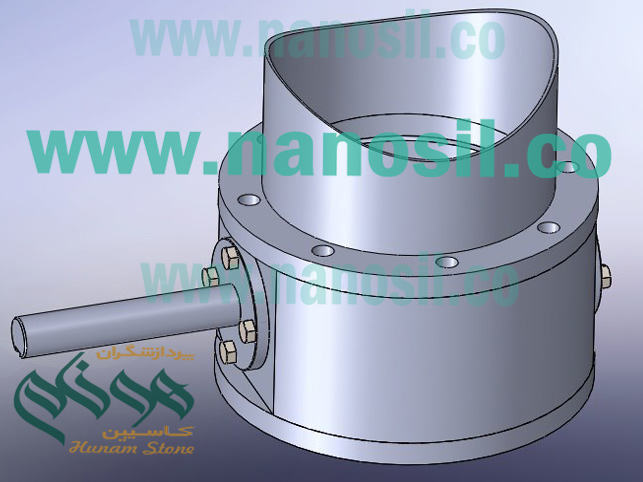

Two-piece vibrating hopper Has a motor vibrator For maintenance Aggregate and alternative materials, Also for maintenance Raw materials for powdered and pasty tile adhesives With an electro motor of 500 kg Three Phases of Special Change: two part hopper is split two to loading at a time, from two different minerals Which is reinforced with a 6 mm sheet It has been done. Installation of the exit gate with two parts of chains with two separate motors 5.5 hp Together with two 5/5 inverters

Artificial stone production line 900 square meters per Shift :Mixer production line with a capacity of 900 square meters With three-phase motor 30 horse / 22 kilowatts / And direct coupling gearbox Customized Turkey , Anti-wear blades, Thickness of the sheet 20 mm and Wall thickness 8 mm , the diameter of the mixer is 190 centimeter , body height of the mixer is 70 cm. capacity of this mixer According to the dimensions of 2/2 cubic meters or 2200 liters will be, Specially adjustable arm 60 mm To number 8 centrifugal Pan design, Plus 2 additional arms to produce powdery and pasty adhesives, Has one exit part With a radius of about 40 cm Automatic material as a powerful pneumatic - Special valve And the respective protective control pneumatically - With emergency control valve - Lola Mixer In the form of a bearing. The capacity of this mixer is 1500 kg Ordinary mass volume of artificial stone, Capacity of concrete from 1700 to 2200 kg According to the formulation, Artificial Stone Capacity of lightweight Equivalent 2000 to 2300 kg density is normal, Mixer build capacity For pasty adhesive With a capacity of 2200 to 2500 kg And powdery glue Capacity 2500 to 3000 kg According to formulation and ...

Artificial stone production line 900 square meters per Shift :Mixer production line with a capacity of 900 square meters With three-phase motor 30 horse / 22 kilowatts / And direct coupling gearbox Customized Turkey , Anti-wear blades, Thickness of the sheet 20 mm and Wall thickness 8 mm , the diameter of the mixer is 190 centimeter , body height of the mixer is 70 cm. capacity of this mixer According to the dimensions of 2/2 cubic meters or 2200 liters will be, Specially adjustable arm 60 mm To number 8 centrifugal Pan design, Plus 2 additional arms to produce powdery and pasty adhesives, Has one exit part With a radius of about 40 cm Automatic material as a powerful pneumatic - Special valve And the respective protective control pneumatically - With emergency control valve - Lola Mixer In the form of a bearing. The capacity of this mixer is 1500 kg Ordinary mass volume of artificial stone, Capacity of concrete from 1700 to 2200 kg According to the formulation, Artificial Stone Capacity of lightweight Equivalent 2000 to 2300 kg density is normal, Mixer build capacity For pasty adhesive With a capacity of 2200 to 2500 kg And powdery glue Capacity 2500 to 3000 kg According to formulation and ...

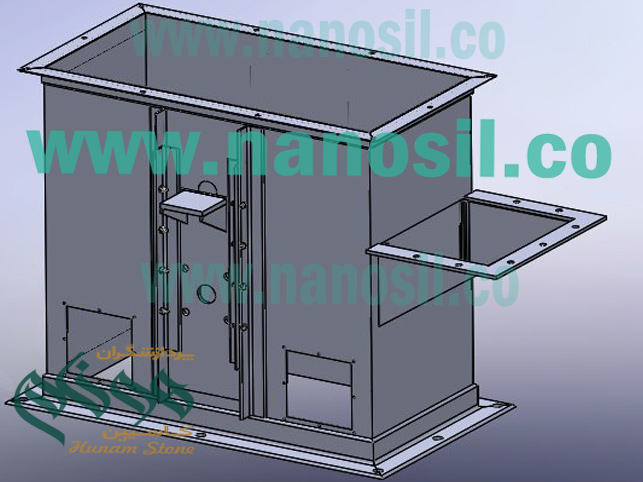

Elevator height the artificial stone production line 900 SQM Compared to other lines It has changed from 7.5 meters to 8.5 meters. also 10-horsepower engine has been used

Elevator height the artificial stone production line 900 SQM Compared to other lines It has changed from 7.5 meters to 8.5 meters. also 10-horsepower engine has been used

Elevator profile artificial stone production line 900 SQM: Automatic transport of aggregates (Adhesive compounds) With a capacity of 350 kg per minute And entry and exit gate At an altitude of 830 centimeters, with three-phase motor 5/7 horsepower, With special custom envelopes And the double edge And Taiwan chains and ...with Hopper weighing After Elevator and before the mixer For weighing materials Jack 125 x 400 strong pneumatic cylinders,With floor hinges and battalion ocular and control of wind protector and the electric valve pneumatic relevant.

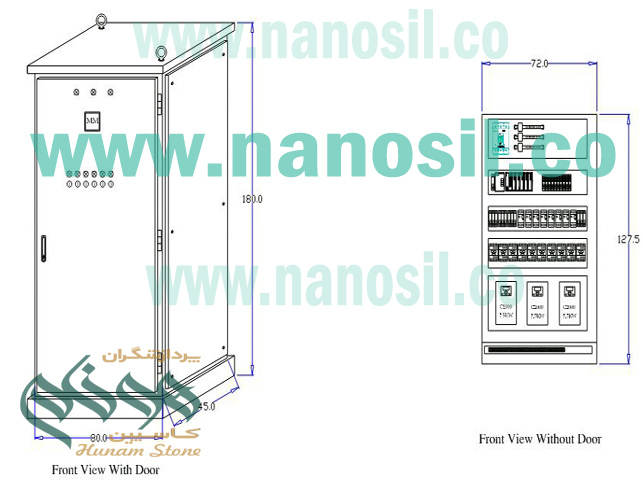

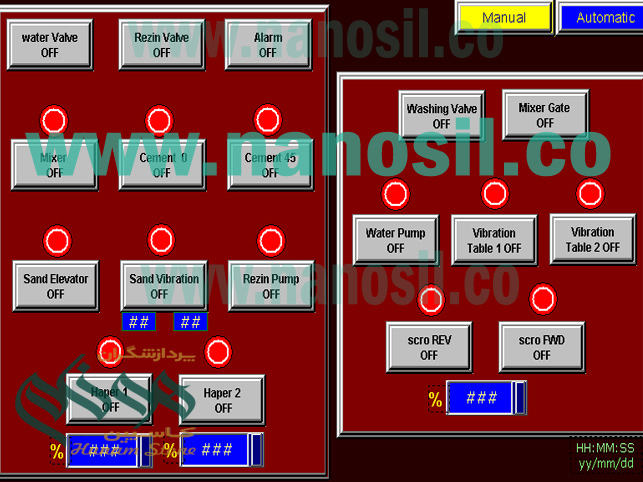

The touch monitor of this production line It's the same as a 10 inch automatic:Power system And the central controller of the device and equipment, With mother computer To control and command all machines With corresponding monitors, With reports from 1000 the previous production-Equipped with a 10-inch color touchscreen-Schneider Germany electrical appliances And Telecom France And Delta-With new planning

The touch monitor of this production line It's the same as a 10 inch automatic:Power system And the central controller of the device and equipment, With mother computer To control and command all machines With corresponding monitors, With reports from 1000 the previous production-Equipped with a 10-inch color touchscreen-Schneider Germany electrical appliances And Telecom France And Delta-With new planning

Vibration table automatic artificial stone : In this production line Like dimensions And the specifications are automatic lines,But due to more production capacity than Two vibrating tables have been used And They are parallel to each other for 4 exit valves. Dimensions 3 × 2 meter with 8 mm plate With two 1300 kg Chinese three-phase engines along with table and tray and four 50*50 cm scales - Chassis 16 and broad wing central chassis, with the spring 8 number and Aerodynamics surface sheet.

Vibration table automatic artificial stone : In this production line Like dimensions And the specifications are automatic lines,But due to more production capacity than Two vibrating tables have been used And They are parallel to each other for 4 exit valves. Dimensions 3 × 2 meter with 8 mm plate With two 1300 kg Chinese three-phase engines along with table and tray and four 50*50 cm scales - Chassis 16 and broad wing central chassis, with the spring 8 number and Aerodynamics surface sheet.

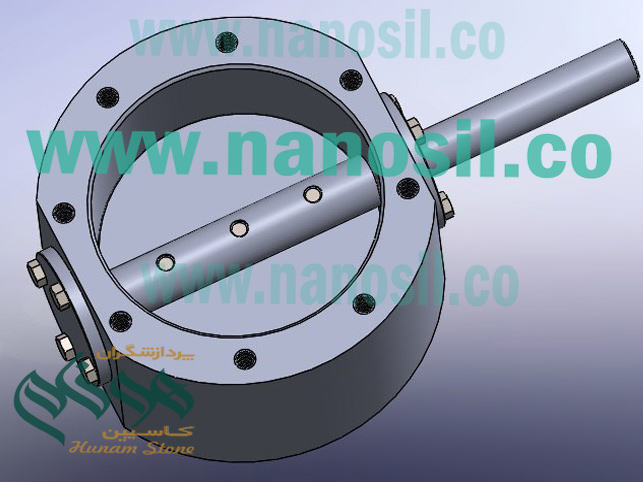

Screw molding in this production line from 480 cm to 700 cm has been changed. The hopper with a capacity of 1500 kg, Exit valve and Molding materials with 4 valves Equipped with valve controls In the form of Pneumatic Butter-fly solenoid valve accessories And the control of pneumatic protectors for four valves is considered, motor with engine power of 10 HP And a special halo shaft gearbox For artificial stone 900 SQM production line molding system Is considered.

Raw material in the hopper load cell weighing system with single moment has been built. The capacity of this hopper is 1000 kg.

Raw material in the hopper load cell weighing system with single moment has been built. The capacity of this hopper is 1000 kg.

Weighing system With four displays Along with the pedal To control pneumatic valves Digital remote control And 10 hp inverter with Tube Manisman And 8 mm screw plate and ...Other changes in this section.

Weighing system With four displays Along with the pedal To control pneumatic valves Digital remote control And 10 hp inverter with Tube Manisman And 8 mm screw plate and ...Other changes in this section.

900 square meter artificial stone production line (With the ability to produce all kinds of antique stones And building façade, types of Floor and mosaic and stone steps, Types of street and polymer curbs, tile glue and Building glue and ...) installing and setting up the factory | Below are pictures of the installation end of the first step; Please see the images for the final installation of 900 square meter automatic production line machines (And other production lines)To gallery of images and section Cement Plast Production Line | Artificial Stone Cement Plast machines , Please refer.