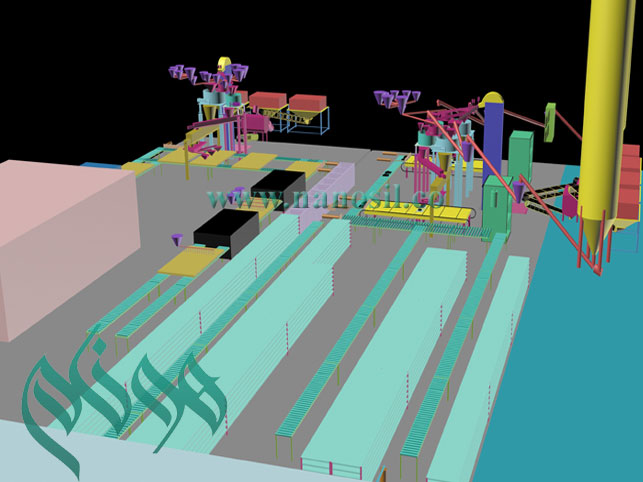

Technical Specification of the automatic cement plast concrete marble-granite artificial stone production line With Capacity 350-400 & 450-500 SQM per shift

Automatic nano cement plast concrete marble & granite facade and mosaic different design artificial stone production line with the produce capacity 300-350 and 450-500 sqm in every work shift along with technology and technical knowledge transfer and training courses at the site of the project

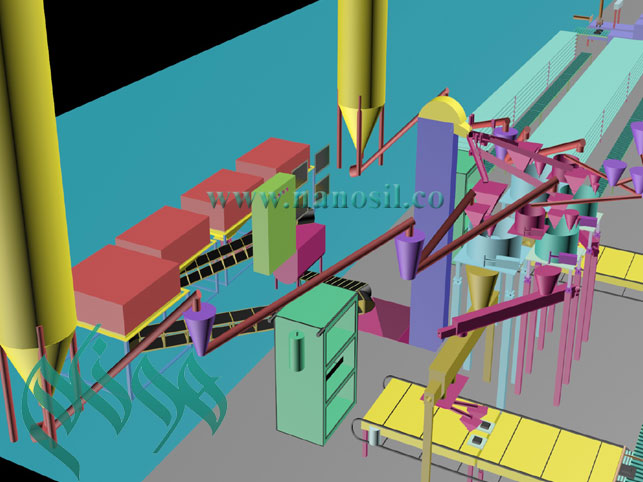

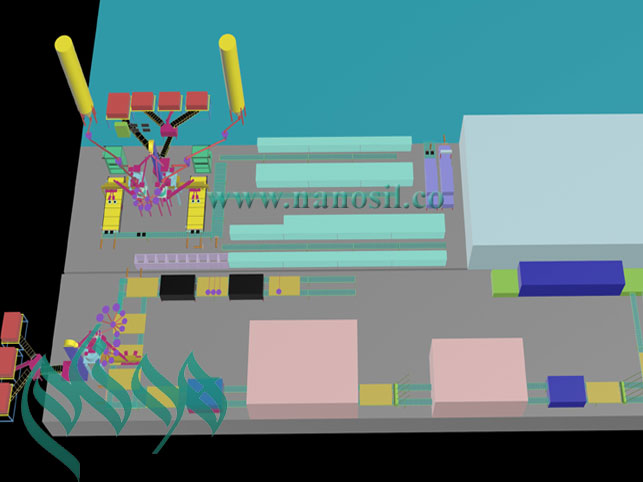

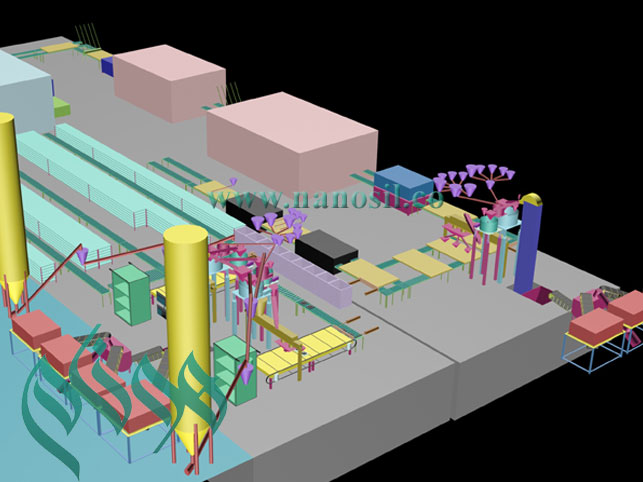

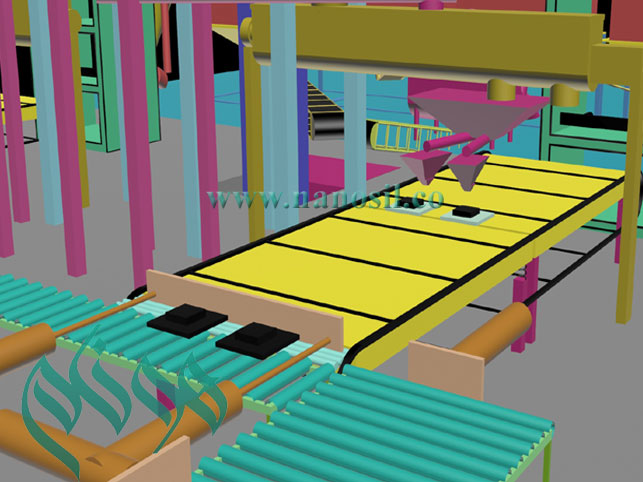

Machinery and equipment automatic production line of artificial stone cement Plast concrete marble includes: Screw by screw artificial stone production line, elevator and vibrating hopper, special mixer-artificial stone cement Plast centrifuge designs pan, Screw injection and molding mixing cement plast artificial stone, artificial stone cement Plast vibrating table vertical 6 square meters, the panel central control system and to determine the dosage of raw materials and polymer materials, sensors detect the reaction of artificial stone cement Plast nano concrete marble and determine the dosage of raw materials, the system loads the add-stone cement Plast and raw materials, tensile is.

Machinery and equipment automatic production line of artificial stone cement Plast concrete marble includes: Screw by screw artificial stone production line, elevator and vibrating hopper, special mixer-artificial stone cement Plast centrifuge designs pan, Screw injection and molding mixing cement plast artificial stone, artificial stone cement Plast vibrating table vertical 6 square meters, the panel central control system and to determine the dosage of raw materials and polymer materials, sensors detect the reaction of artificial stone cement Plast nano concrete marble and determine the dosage of raw materials, the system loads the add-stone cement Plast and raw materials, tensile is.

This production line capable of producing different types of artificial stone cement Plast, artificial stone siding for interior and exterior decoration, concrete marble , all kinds of stone stairs and under the stairs nano cement-plast, stone baseboard, flooring and antique flooring, façade artificial stone cement Plast, able to produce glue tile paste and powder, cement concrete and concrete additives, and construction adhesives and resins and additives for concrete and building materials chemistry, engineering nano-glass stone will be produced artificial stone.

Including automatic production line of artificial stone cement Plast education services and building products and technology transfer This series product line can be as follows

Including automatic production line of artificial stone cement Plast education services and building products and technology transfer This series product line can be as follows

Early Learning: The period of technology transfer, artificial stone (artificial stone cement Plast nano) and other technology building contract includes 6 days in office,human artificial stone ( now hunam processors ) are theoretically Secondary education (after installation): applicant after receiving basic training artificial stone cement Plast technology and other technologies as well as booklets provided training formula, are obliged to supply the raw materials required, the form of artificial stone cement Plast, and equipment manufacturing and according to the situation and coordinate relevant matter to the researcher has announced.

Secondary education (after installation): applicant after receiving basic training artificial stone cement Plast technology and other technologies as well as booklets provided training formula, are obliged to supply the raw materials required, the form of artificial stone cement Plast, and equipment manufacturing and according to the situation and coordinate relevant matter to the researcher has announced.

Secondary education is for 2 to 3 days and in the realization of practical technology provided to the applicant

Third Training Time (Training and calibration devices, etc.) (special automatic and semi-automatic production line of artificial stone cement Plast) (post-secondary education) and hold it for a day or two after installation setting up machinery equipment and training complex at the site of the project will be done

Third Training Time (Training and calibration devices, etc.) (special automatic and semi-automatic production line of artificial stone cement Plast) (post-secondary education) and hold it for a day or two after installation setting up machinery equipment and training complex at the site of the project will be done

Providing technology products, artificial stone cement Plast includes the formulation of polymeric materials and nano compounds according to the results of testing of raw materials, soil and weather conditions and the type and color of cement production (temperature, humidity, etc.)

Providing technology products, artificial stone cement Plast includes the formulation of polymeric materials and nano compounds according to the results of testing of raw materials, soil and weather conditions and the type and color of cement production (temperature, humidity, etc.)

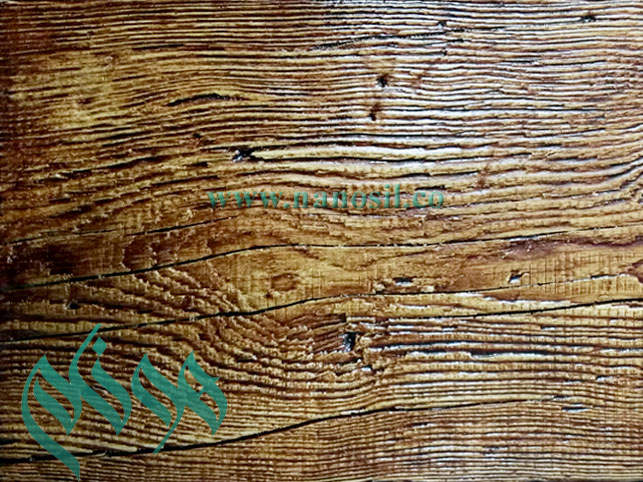

and the standard, Antique stone facade and a variety of plastic foam cement, the production of multi-phase training, with many color variations and color making too much of this technology according to customer requests, laminated methods of creating artificial stone cement-Plast-education, manufacturing formulas similar in technology and construction of natural stone, artificial stone and artificial stone cement Plast engineering (Creating marble, granite, travertine and stone in artificial stone cement Plast engineering)

formulation and education normal volume mass production of artificial stone cement Plast (2200 kg per cubic meter), artificial stone cement Plast medium education formula (1500-1700 kg qbm ) product training and antique formulas, artificial stone cement Plast light for facade (1100 kg cubic meter density) ultralight training products, artificial stone ،under 1000 kd in qbm, familiarity applicant surrounding markets and provide important factor in marketing and sales of artificial stone and other technologies to increase the power of marketing and sales of the applicant production line technology.

consulting in the field of artificial stone cement Plast best-selling and most widely used format to suit the tastes geographical area applying technology and the buyer artificial stone production line, as well as providing all documents and contract formulation and production launch and supply of all raw materials indefinitely

Training and production formula more than 20 different product types used in the ceramics industry-Ceramic and Stone (Construction Adhesives technology) pasty tile adhesive Ready (in two different types, and especially to Normal) Tile adhesive powder in various forms in two basic types , creating structural primers for plaster (used in the installation of stone, paint and primer painting and anti-dandruff and waterproof plaster).

Training and production formula more than 20 different product types used in the ceramics industry-Ceramic and Stone (Construction Adhesives technology) pasty tile adhesive Ready (in two different types, and especially to Normal) Tile adhesive powder in various forms in two basic types , creating structural primers for plaster (used in the installation of stone, paint and primer painting and anti-dandruff and waterproof plaster).

concrete adhesive to create more cohesion and elasticity, adhesive powder additives and adhesives for the installation of lightweight concrete in two different types of paste sealant health services, jointing colored powders in different colors, of joint anti-bacterial powder, a variety of construction and industrial grout in several different compounds with high adhesion strength.

method of production technology extremely rough stones at an angle positive and negative with very low cost for interior decoration of buildings (and cellulose coatings and Antique), formulation of synthetic resin shiny and matte for natural stone and resin for waterproofing as well as the formulation of luminescent, anti fat, anti-UV, etc.

along with the corresponding formulation and raw material supply contracts for unlimited and after-sales service

Training and transfer new techniques of painting and laminated artificial stone cement Plast with different ways (special techniques) for interior and exterior decoration with very specific colors to the beauty and value-added products as well as frequent training and other services to learn newer techniques and more services in the future

Training and transfer new techniques of painting and laminated artificial stone cement Plast with different ways (special techniques) for interior and exterior decoration with very specific colors to the beauty and value-added products as well as frequent training and other services to learn newer techniques and more services in the future

Time to install automatic production line machinery, artificial stone cement Plast as hard and software for 10 to 14 days in the applicant's place of technology

Advantages automatic artificial stone nano cement plast concrete marble production line machines

Loading of raw material is automatically along with the quality control of the materials

The ability to choose two formulas for the mixture by the central controller

The ability to choose 99 pigmentation formulas and recording the mixing proportions

The ability for frequent reporting about the production process and ability to connect to the computer

Automatic scanning of the mixture (25 scans per second) to assess chemical reactions and determination of raw material dosage

Detection of the preparation of the mixture and automatic command to discharge valves

Simultaneously Injection of the mixture to the molds using two pneumatic valves

Automatic self-washing along with primary filtration of the output

Disadvantages for artificial stone production line machine: no disadvantages detected Advantages of automatic system compared with manual artificial stone production line

Advantages of automatic system compared with manual artificial stone production line

The central computer exactly controls the completion of the production process ,so the reactions are completely done

The color of the products is equal in every batch ,because the central computer exactly controls the humidity and temperature

Equal quality and strength of the products in every batch

production process is speedy because loading and discharging of the mixer is automatic

There's no need for trained and lots of manpower

No squander in raw material because of the exact control of the dosage of materials

The surface of the product is quite unruffled because of the exact control of the used water and resin toward temperature variations of the environment

High accuracy in creating desired colors in different batches

Artificial stone cement Plast second type of automatic production line with a capacity of 650 to 700 square meters per shift

Artificial stone cement Plast second type of automatic production line with a capacity of 650 to 700 square meters per shift

This collection (automatic production line of artificial stone cement Plast II) the same automatic with a capacity of 700 square meters is just twins.

Due to the use of some common devices, as well as some shared staff and production operators, the cost of setting up a host Less than two automatic production line of artificial stone is, and that the cost of the production in this production line is between 10% and 15% lower than the first type.

The amount of space required for a second production line of the two line separately, will be much less. To learn more about In this case, full description is presented in person)